LongRifles, Inc.

About the Status Tracker

EFB

Engraving, Fluting, Bolt Work

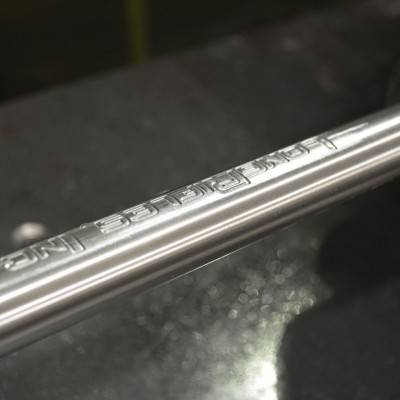

LongRifles, Inc. offers a broad range of barrel fluting options. Straight, helical, diamond, and helical-interrupted fluting patterns are available. Our cutter geometry delivers a unique "industrial appearance" to a finished barrel and eliminates the razor sharp edges common to deeply fluted barrels. The use of CNC machining centers, modern insert cutter geometry, and rock solid work holding allow us to deliver inclusion free surface finishes for an exceptional presentation when left "in the white" or coated with Cerakote.

We've performed this service to hundreds of barrels made using both the single point and button rifling methods of manufacturing. It's been demonstrated over and over again that our process has zero effect on accuracy.

Barrel fluting is largely cosmetic. Because of this we prefer our clients to allow us some "artistic freedom" with the flute count and depth. Because of the cutter design, sometimes it's beneficial to increase or reduce the number of flutes so that the finished appearance is symmetrical. This is one of the rare cases in machine work where "if it looks right, it is right."

Weight reduction. Probably the single most asked question regarding fluting a barrel. We recognize the need to lighter weight guns when the application involves extreme duty such as a high alpine sheep rifle where every ounce counts. Our online fluting calculator accurately estimates the amount of weight reduction you can expect from your barrel. You will find the fluting calculator on any of the barrel product pages of this site.

Tools Home

EFB

Engraving, Fluting, Bolt Work

LongRifles, Inc. offers a broad range of barrel fluting options. Straight, helical, diamond, and helical-interrupted fluting patterns are available. Our cutter geometry delivers a unique "industrial appearance" to a finished barrel and eliminates the razor sharp edges common to deeply fluted barrels. The use of CNC machining centers, modern insert cutter geometry, and rock solid work holding allow us to deliver inclusion free surface finishes for an exceptional presentation when left "in the white" or coated with Cerakote. We've performed this service to hundreds of barrels made using both the single point and button rifling methods of manufacturing. It's been demonstrated over and over again that our process has zero effect on accuracy. Barrel fluting is largely cosmetic. Because of this we prefer our clients to allow us some "artistic freedom" with the flute count and depth. Because of the cutter design, sometimes it's beneficial to increase or reduce the number of flutes so that the finished appearance is symmetrical. This is one of the rare cases in machine work where "if it looks right, it is right." Weight reduction. Probably the single most asked question regarding fluting a barrel. We recognize the need to lighter weight guns when the application involves extreme duty such as a high alpine sheep rifle where every ounce counts. Our online fluting calculator accurately estimates the amount of weight reduction you can expect from your barrel. You will find the fluting calculator on any of the barrel product pages of this site.

Tools Home